What is Polypropylene (PP), and What is it Used For?

Polypropylene (PP) is a thermoplastic “addition polymer” made from the combination of propylene monomers. It is used in a variety of applications to include packaging for consumer products, plastic parts for various industries including the automotive industry, special devices like living hinges, and textiles.POLYPVC provides high quality and cheap price PP materials in any conditions and meet all your requirements with customization.

What are the Characteristics of Polypropylene?

- Chemical Resistance

- Elasticity and Toughness

- Fatigue Resistance

- Transmissivity

Types of PP material

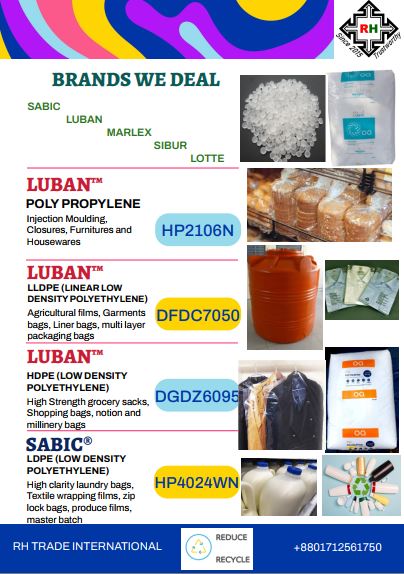

There are two main types of polypropylene available: Homopolymers and Copolymers. The copolymers are further divided into block copolymers and random copolymers. Each category fits certain applications better than the others. Polypropylene is often called the “steel” of the plastic industry because of the various ways in which it can be modified or customized to best serve a particular purpose. This is usually achieved by introducing special additives to it or by manufacturing it in a very particular way. This adaptability is a vital property.

What is PE and PE material?

Polyethylene (PE) is a polymer mainly used for packaging such as plastic bags, plastic films, geomembranes and containers, including bottles, etc.

Polyethylene is divided into high density polyethylene (HDPE), low density polyethylene (LDPE) and linear low density polyethylene (LLDPE) according to polymerization method, molecular weight and chain structure.

- Low density polyethylene (LDPE)Properties:Tasteless, odorless, non-toxic, matte surface, milky waxy particles, density of about 0.920g /cm3, melting point 130℃ ~ 145℃. Insoluble in water, slightly soluble in hydrocarbons, etc. Resistance to most acid and alkali erosion, water absorption is small, at low temperature can still maintain softness, high electrical insulation.USES:Can use injection molding, extrusion, blow molding and other processing methods. Mainly used for agricultural film, industrial packaging film, medicine and food packaging film, machinery parts, daily necessities, building materials, wire, cable insulation, coating and synthetic paper.

- Linear low density polyethylene (LLDPE)Properties:Because the molecular structure of LLDPE and LDPE is obviously different, the performance is also different. Compared with LDPE, LLDPE has excellent environmental stress cracking resistance and electrical insulation, higher heat resistance, impact resistance and puncture resistance. Production process: LLDPE resin is mainly produced by full density polyethylene unit, and the representative production process is Innovene process and Unipol process of UCC.USES:Through injection molding, extrusion, blow molding and other molding methods, production of film, daily necessities, pipes, wires and cables, etc

- High density polyethylene (HDPE)Nature: natural color, cylindrical or flat round particles, particles smooth, particle size in any direction should be 2 mm ~ 5 mm, no mechanical impurities, thermoplastic.Production process:Two production processes, gas phase method and slurry method, are adopted. USES:By injection molding, blow molding, extrusion, rolling molding and other molding methods, we produce film products, daily necessities and various sizes of industrial hollow containers

Reviews

There are no reviews yet.